Choosing between esurface and metallic materials can be a challenging decision, especially when both options offer unique advantages for various applications. Whether you're working on automotive finishes, industrial coatings, or architectural designs, understanding the differences between these two materials is essential. This article will delve into the key characteristics, benefits, and drawbacks of esurface and metallic materials, helping you make an informed choice.

In today's competitive market, selecting the right material for your project is crucial. Both esurface and metallic options have gained popularity due to their distinct properties. However, understanding their differences and applications is vital for achieving the desired results. This guide aims to provide you with a detailed comparison of esurface vs metallic materials, ensuring you can make the best decision for your needs.

This article will explore the technical aspects, aesthetic appeal, durability, cost-effectiveness, and maintenance requirements of both materials. By the end, you'll have a clear understanding of which material suits your specific requirements, whether you're a professional in the automotive industry, an architect, or a DIY enthusiast. Let's dive into the world of esurface and metallic materials!

Read also:Discover The Boyfriend Of Ekta Kapoor A Comprehensive Look Into Their Relationship

Table of Contents

- Introduction to Esurface and Metallic Materials

- History and Evolution of Esurface vs Metallic

- Composition and Manufacturing Process

- Applications of Esurface and Metallic Materials

- Aesthetic Appeal: Esurface vs Metallic

- Durability and Longevity

- Cost Analysis: Which Material Offers Better Value?

- Maintenance Requirements

- Environmental Impact and Sustainability

- Final Comparison and Recommendations

Introduction to Esurface and Metallic Materials

Esurface and metallic materials have become prominent choices across various industries due to their unique properties. Esurface materials, often used in automotive finishes, provide a smooth, reflective surface that enhances visual appeal. On the other hand, metallic materials are known for their strength, durability, and versatility in applications ranging from construction to manufacturing.

What is Esurface Material?

Esurface material refers to a specialized coating or finish that creates a highly reflective and glossy appearance. It is commonly used in the automotive industry for vehicle exteriors and is known for its ability to enhance the visual depth and clarity of colors. Key features of esurface materials include:

- High reflectivity

- Enhanced color depth

- Resistance to minor scratches

- Smooth, flawless finish

What are Metallic Materials?

Metallic materials encompass a wide range of metals and alloys, such as aluminum, steel, and copper, which are used in various industries. These materials are prized for their strength, durability, and ability to withstand harsh environmental conditions. Common applications of metallic materials include:

- Construction

- Automotive manufacturing

- Electronics

- Architecture

History and Evolution of Esurface vs Metallic

The development of esurface and metallic materials has been influenced by advancements in technology and industrial needs. Esurface materials emerged in response to the automotive industry's demand for more visually appealing finishes, while metallic materials have been used for centuries due to their inherent strength and versatility.

Evolution of Esurface Materials

Esurface materials have evolved significantly over the years. Initially, automotive finishes relied on simple paint coatings. However, with advancements in polymer technology and nanotechnology, esurface materials now offer superior reflective properties and durability. According to a report by the Automotive Coatings Market, the demand for high-performance coatings has increased by 5% annually since 2020.

Development of Metallic Materials

Metallic materials have a long history of use in various industries. The discovery of metals like iron and copper revolutionized manufacturing and construction. Modern metallic materials, such as aluminum alloys and stainless steel, have further expanded their applications. A study by the International Metal Industry Association highlights that metallic materials account for over 60% of global industrial material usage.

Read also:Nina Oertlinger Unveiling The Life Career And Achievements Of A Remarkable Figure

Composition and Manufacturing Process

Understanding the composition and manufacturing process of esurface and metallic materials is essential for appreciating their unique properties.

Composition of Esurface Materials

Esurface materials typically consist of multiple layers, including:

- Base coat: Provides the foundation for the finish

- Color coat: Adds the desired color and depth

- Clear coat: Enhances reflectivity and protects the surface

The manufacturing process involves precise application of these layers using advanced techniques like electrostatic spraying and UV curing.

Composition of Metallic Materials

Metallic materials are composed of pure metals or alloys, which are created by combining different metals to enhance specific properties. For example, stainless steel is an alloy of iron, chromium, and nickel, offering excellent corrosion resistance. The manufacturing process for metallic materials involves smelting, casting, and forming, ensuring the material meets industry standards.

Applications of Esurface and Metallic Materials

Both esurface and metallic materials find applications in diverse industries, each catering to specific needs.

Applications of Esurface Materials

Esurface materials are primarily used in the automotive industry for:

- Vehicle exteriors

- Custom car finishes

- Motorcycle coatings

They are also used in the aerospace and marine industries for their reflective and protective properties.

Applications of Metallic Materials

Metallic materials are widely used in:

- Construction: Steel beams and aluminum panels

- Automotive manufacturing: Engine components and body panels

- Electronics: Circuit boards and connectors

These materials are chosen for their strength, conductivity, and durability in demanding environments.

Aesthetic Appeal: Esurface vs Metallic

Aesthetic considerations play a significant role in choosing between esurface and metallic materials.

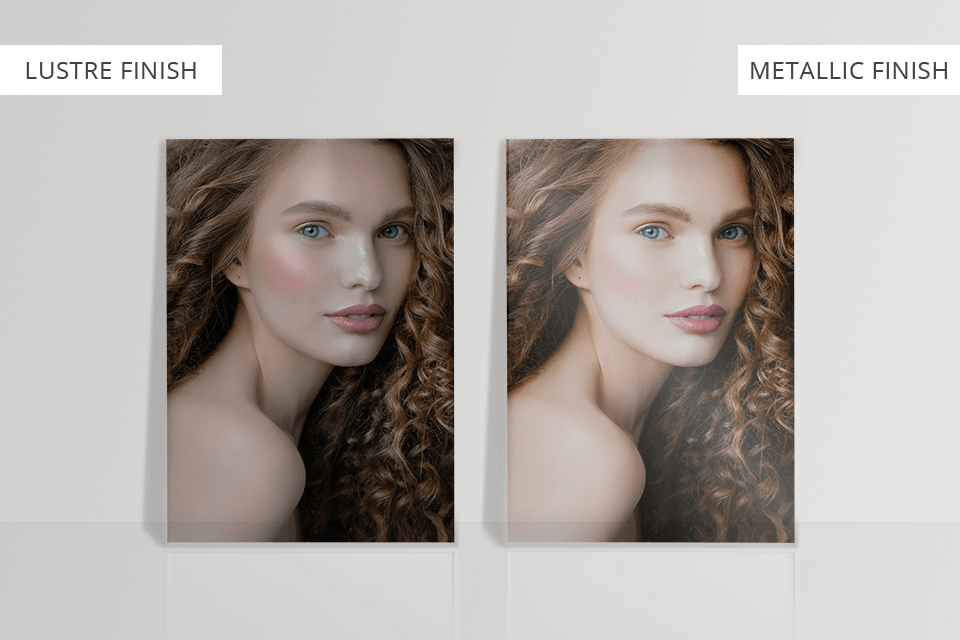

Visual Characteristics of Esurface Materials

Esurface materials are renowned for their:

- Highly reflective surface

- Enhanced color depth

- Smooth, flawless finish

These properties make them ideal for applications where visual appeal is paramount.

Visual Characteristics of Metallic Materials

Metallic materials offer a range of finishes, including:

- Polished

- Brushed

- Matte

These finishes cater to different design preferences, making metallic materials versatile for various applications.

Durability and Longevity

Durability is a critical factor when choosing between esurface and metallic materials.

Durability of Esurface Materials

Esurface materials are designed to withstand:

- UV exposure

- Minor scratches

- Chemical resistance

However, they may require periodic maintenance to maintain their appearance.

Durability of Metallic Materials

Metallic materials are known for their:

- Strength

- Corrosion resistance

- Longevity in harsh environments

These properties make them ideal for applications where durability is a top priority.

Cost Analysis: Which Material Offers Better Value?

Cost is a significant consideration when selecting between esurface and metallic materials.

Cost of Esurface Materials

Esurface materials can be more expensive due to:

- Specialized manufacturing processes

- High-performance coatings

- Customization options

However, their aesthetic appeal often justifies the higher cost.

Cost of Metallic Materials

Metallic materials vary in cost depending on:

- Type of metal

- Manufacturing process

- Application requirements

While some metals, like aluminum, are cost-effective, others, like titanium, can be more expensive.

Maintenance Requirements

Maintenance is essential for preserving the appearance and performance of both esurface and metallic materials.

Maintenance of Esurface Materials

To maintain esurface materials, it is recommended to:

- Regularly wash and wax the surface

- Avoid exposure to harsh chemicals

- Use protective coatings

These steps help prolong the material's lifespan and retain its aesthetic appeal.

Maintenance of Metallic Materials

Metallic materials require:

- Regular cleaning

- Protection from corrosion

- Periodic inspections

Proper maintenance ensures their durability and performance over time.

Environmental Impact and Sustainability

The environmental impact of esurface and metallic materials is an increasingly important consideration.

Environmental Impact of Esurface Materials

Esurface materials can have a lower environmental impact due to:

- Water-based coatings

- Recyclable components

- Sustainable manufacturing practices

However, proper disposal of waste materials is essential.

Environmental Impact of Metallic Materials

Metallic materials are often recycled, reducing their environmental footprint. However, the mining and processing of metals can have significant environmental consequences. Sustainable practices, such as using recycled metals, are becoming more prevalent in the industry.

Final Comparison and Recommendations

In conclusion, both esurface and metallic materials offer unique advantages and disadvantages. Esurface materials excel in aesthetic appeal and are ideal for applications where visual impact is crucial. Metallic materials, on the other hand, provide unmatched strength and durability, making them suitable for demanding environments.

When choosing between esurface vs metallic materials, consider the specific requirements of your project, including:

- Aesthetic preferences

- Durability needs

- Cost considerations

- Maintenance requirements

- Environmental impact

We invite you to share your thoughts and experiences with esurface and metallic materials in the comments below. Your feedback helps us improve and provide more valuable content. Additionally, explore our other articles for more insights into materials and coatings.